Supply Chain Transformation

/ A Bespoke Approach for Supply Chain Resilience

Uncertainty and convoluted crisis impact businesses across the globe. However, the same conditions can have vastly different impacts on the supply chains of companies in the same industry. For example, a silicon manufacturer may face significant problems in its supply chain during a disruption such as the COVID 19 pandemic, while a company that manufactures healthcare products may not face logistical problems in the same crisis given the relevance of their products in this very crisis. A company that manufactures films for house surfaces, may even experience a boom in demand during the same crisis situation.

Dealing with extreme uncertainty and external shocks in globalized supply and transportation chains requires the ability to adapt while maintaining operational supply chain resilience. Flexibility and proactivity are the prerequisites for identifying opportunities and leveraging market conditions to the company’s advantage. Being reactive is no longer good enough. Despite extensive proactive measures to build resilience, companies have faced a number of disruptions for which they were not adequately prepared, including the Ukraine conflict and the Suez Canal blockade that followed the Covid-19 outbreak.

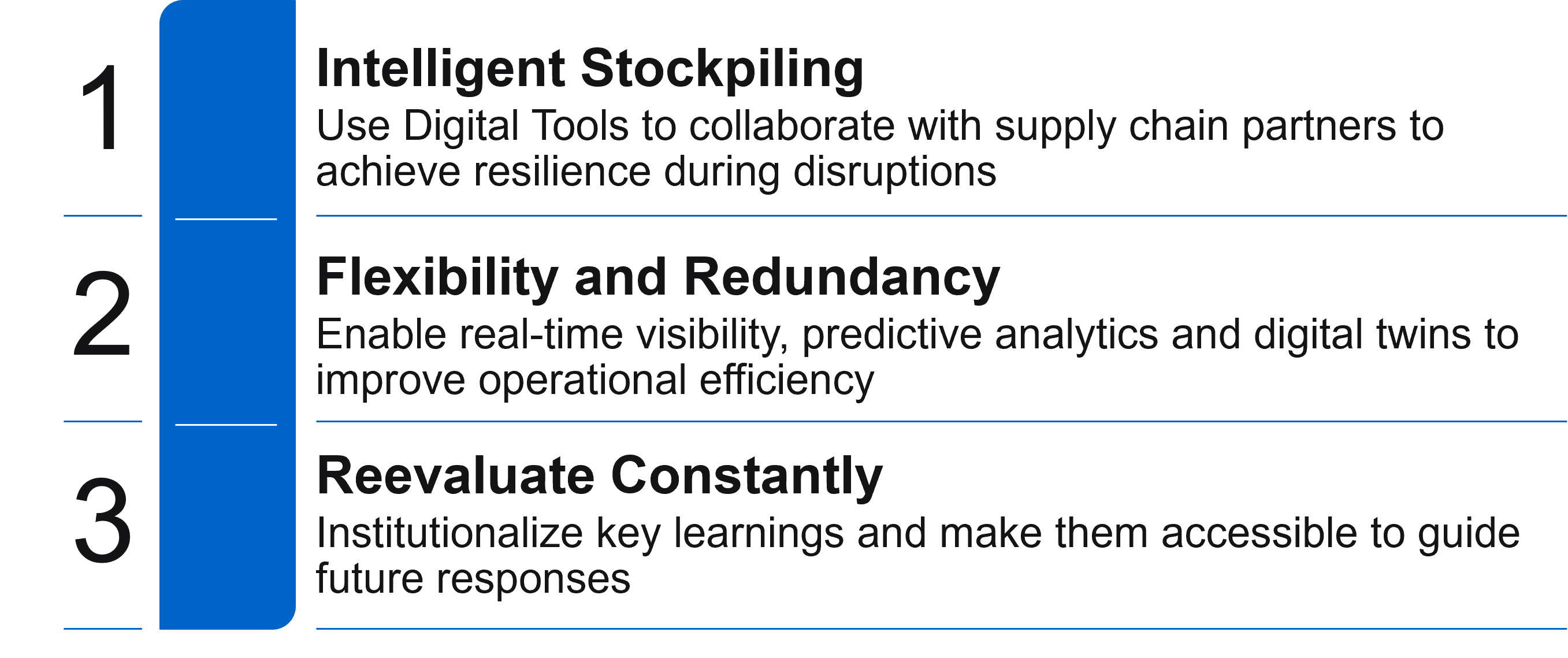

This shows that further ways of optimizing the resilience of the supply chain must be constantly sought to remain competitive in the global market. The importance of different measures varies depending on the size of the company and the products manufactured. In addition, different disruptions affect supply chains differently, so some companies experience negative impacts while others benefit. It is necessary to adopt an approach that requires the intelligent use of internal resources as well as market awareness through the use of digital levers to optimize processes:

Figure 1

/ Opportunities to build supply chain resilience

Source: bluegain Analysis [2023]

/ OPPORTUNITY 1 – INTELLIGENT STOCKPILING

The occurrence and regional nature of raw materials play an important role in determining the actions needed to build resilient supply chains. Stockpiling is essential when a critical raw material comes from a single source. However, if a raw material is sourced from multiple suppliers or delivered on a daily basis, safety stocks are rarely necessary. Resource availability must be assessed both during normal operations and during an interruption. Which resources are delivered only monthly? Are there systemically important resources that cannot be replaced with alternative materials? How much working capital can the company afford to keep in stock? Stockpiling involves determining the optimal storage location, volume and type of materials. Companies can reserve a certain amount of inventory for strategically important customers to ensure business volume. In the event of a disruption, it is necessary to share information and collaborate along the supply chain with both suppliers and customers to find the most appropriate solution for all parties. Digital twins can play a pivotal role in digitally mapping internal material flows and internal bottlenecks along the supply chain.

/ OPPORTUNITY 2 – FLEXIBILITY & REDUNDANCY

Finding the right balance between flexibility and redundancy can be difficult, but it is central to business success in turbulent times. Redundancy, on the one hand, is a crucial strategy for coping with disruptions, which includes a certain amount of leeway in production, variable transport capacities, and multiple procurement and production sites. Flexibility, on the other hand, requires the existence of substitute suppliers and distribution channels, but also volume flexibility and the ability to change suppliers easily. Digital levers can help supply chain leaders to find the right balance between flexibility and redundancy in their operations. By leveraging real-time visibility, predictive analytics, digital twins, supply chain leaders can improve their operational resilience and reduce costs. Additionally, blockchain-based smart contracts can increase flexibility in supply chains by streamlining processes, reducing transaction costs, facilitating the exchange of information, providing transparency and accountability, and improving trust between different stakeholders.

/ OPPORTUNITY 3 – REEVALUATE CONSTANTLY

In light of the COVID-19 pandemic and the resulting disruptions, it has become common for organizations to face crises and disruptions on a regular basis. Even if employees have gained relevant experience in dealing with such situations, continuous training is required in the area of customer communication. In this regard ‘mock calls’ can serve as a useful tool to assess how effectively problems are being addressed and to identify areas for improvement. It is advisable for companies of all sizes to improve their training programs to prepare their employees professionally and psychologically. As part of an organization’s business continuity management, it is critical to conduct regular assessments of all potential risks based on their likelihood and impact to gain a comprehensive understanding of the various threats. In addition, it is essential to collect and document lessons learned from past crises and disruptions, and develop policies to draw on these lessons and best practices in future incidents. These lessons should be stored in a digital knowledge management system that is accessible to all relevant employees in the company. In addition, relevant information should be presented in an understandable and intelligent way on dashboards, including the assessment of the current situation, the development of previous assessments and supporting information.

The new reality will further test the ingenuity, resilience and flexibility of supply chain leaders and our lessons learned. In any case, the supply chain networks of the future must be both resilient and sustainable.

/ ABOUT THE AUTHORS

- Florian Schmatz is an Associate at bluegain, where he started as a Fellow in 2022. Before he worked in the IT department at Freudenberg Sealing Technologies, and at Meetingsbooker.com in Dublin/ Ireland. He holds a Master in International Business at WHU – Otto Beisheim School of Management and a Bachelor in Engineering Economics at Karlsruhe Institute of Technology.

- Dr. Carsten Linz is the CEO of bluegain. Formerly Group Digital Officer at BASF and Business Development Officer at SAP, he is known for building €100 million businesses and leading large-scale transformations affecting 60,000+ employees. He is represented on boards including Shareability’s Technology & Innovation Committee and Social Impact. A member of the World Economic Forum’s Expert Network, Dr. Linz is also a published author who shares his expertise as an educator in executive programs at top business schools.

/ download WHITEPAPER

Empowering you with knowledge is our priority. Explore our collection of well-thought-out whitepapers available for download. Should you have any questions or wish to explore further, our team is here to assist you.

download

back to Article

back to Article